For centuries, the art of quilting has been defined by the rhythmic push and pull of a needle and thread. But in modern textile production, a quieter, faster, and remarkably innovative method has emerged: Ultrasonic Quilting. This technology is transforming how we create padded fabrics, moving beyond traditional sewing to fuse materials with the power of sound.

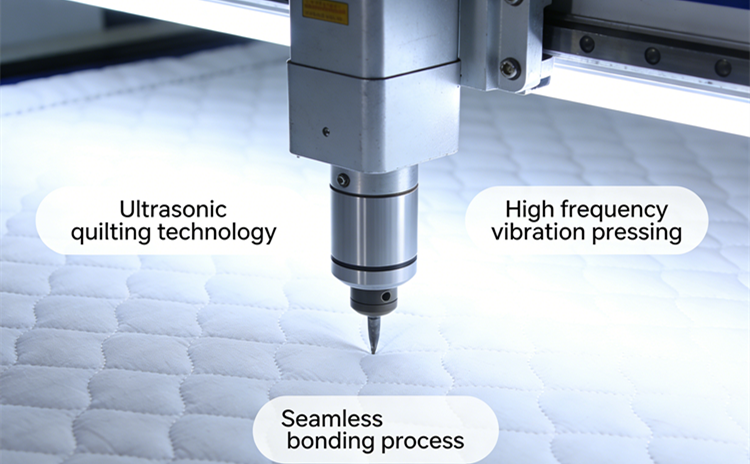

Imagine a quilting machine without a conventional needle, thread, or even heat. Ultrasonic quilting uses high-frequency sound waves to bond layers of fabric together. The heart of the process is an ultrasonic horn, which vibrates at these incredible speeds. When this horn presses against layered textiles—commonly a top fabric, a batting or filler, and a backing fabric—the vibrations are directed to a specific point.

The magic happens through friction. The intense, rapid vibration at the point of contact generates localized heat within the fabric materials themselves, specifically in man-made fabrics containing thermoplastics like polyester or polypropylene. This heat momentarily melts the synthetic fibers, fusing the layers seamlessly at the point of contact. The anvil roller or pattern wheel beneath the fabric often has a raised design, which creates the distinctive quilted pattern as the bond forms.

You likely encounter ultrasonic quilting more often than you think. It’s used in:

Home Textiles: Mattress pad covers, quilted bedspreads, tablecloths, and decorative wall panels.

Fashion & Apparel: Padded jacket linings, athletic wear, handbags, and hats.

Technical Applications: Automotive interiors (headliners, door panels), medical supplies (orthopedic padding, reusable ice packs), and protective gear.

Are there limitations? Absolutely. The process works best with synthetic, thermoplastic-based materials. Natural fibers like 100% cotton or wool, which don’t melt, cannot be bonded this way alone (though blends can work). The initial investment in equipment is also higher than for traditional sewing machines.

In a nutshell, ultrasonic quilting is a brilliant fusion of technology and textile craft. It represents a shift from mechanical stitching to molecular bonding, offering a faster, stronger, and more versatile way to create the textured, padded fabrics we rely on daily.

Learn more: http://www.springtextile.com Or Spring Hometextile video channel: www.youtube.com/channel/UCMCz-yKQMYxA1e2Uscw5PHw Also can contact Tina at: [email protected]